● The Indian government is investing heavily in semiconductor research and manufacturing projects to meet domestic demand.

● An innovative researcher in semiconductors at the Indian Institute of Science, Bangalore, designed chips used in vehicles that can handle different voltage levels.

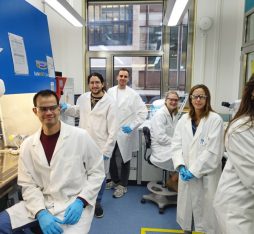

On January 19, the Dutch company NXP, one of the largest semiconductor designers in Europe, inaugurated an R&D laboratory at India’s Tech Park, in Bangalore, to design specific systems for automobiles, IoT and consumer electronics, like radars, NFC technologies and energy-saving chips in cars. Thanks to its expertise, this laboratory should help accelerate long-term production capacities to meet the Indian government’s proactive ambitions to make India a global benchmark in microelectronics. For India, which is experiencing a booming automotive market, the strategic objective is to become more autonomous and develop its own microelectronics industry. “We design many electronic devices, but we are dependent on electronic components manufactured abroad, like semiconductors,” laments Mayank Shrivastava. After working in the United States at Infineon and in Germany at Intel, the researcher specializing in nanotechnology moved back to India where he teaches at the Indian Institute of Science, Bangalore.

India already imports more electronic components than oil. Shrivastava believes this is just the beginning, as 6G will make demand skyrocket.

Colossal investments

Although India is known for designing electronic chips, and has nearly 20,000 engineers working in the industry, the country doesn’t yet have companies capable of producing semiconductors. India’s import share is also set to quadruple in the coming years. “India imports more electronic components than oil. And this is only the beginning, as demand will skyrocket with the advent of 6G,” cautions Shrivastava. Because the market is being reorganized, the Indian government aims to double its semiconductor market to $64 billion by 2026, according to the India Electronics and Semiconductor Association. In order to compete against dominant players like Taiwan and South Korea, India subsidizes up to 50% of the construction of screen and semiconductor factories, which often require multi-billion dollar investments.

Managing different voltage levels in vehicles

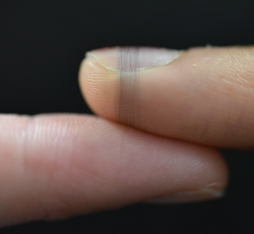

In the context of a government-funded project, Shrivastava, in collaboration with local industrialists, has developed a semiconductor dedicated to energy management in electronic chips to reduce India’s economic dependence and respond to major technical challenges for the automotive market. This technology also aims to extend the life of electronic parts. “Microprocessors are used in vehicles, for data processing, sensors, signal processing, as well as chips dedicated to energy processing,” said Shrivastava. Already holding many patents in the industry, Shrivastava said he has solved a major issue facing the market. “Unlike smartphones, cars needs to manage very high voltages,” to feed the antenna communicating with the outside world and sensors transforming specific signals, for example. “We designed a range of on-chip electrical switches, , that meet the needs of vehicles and could potentially be adopted more widely in other markets, as they can handle greater amplitudes of different voltages.” While microprocessors function with very low voltages of around 1V, Indians hope their partner manufacturers will take advantage of this innovation to in turn export their own expertise.