Do It Yourself (DIY) first appeared in the United States in the 1960s, surfing the wave of the hippie movement and its communities. In Europe, an Italian architect, Enzo Mari (only in French), launched the concept in the 1970s: he gave out plans allowing people to make his wooden furniture themselves free of charge, a somewhat utopian idea at the time, which was developed further by the Massachusetts Institute of Technology (MIT) in the late 1990s with the “FabLabs” (Fabrication Laboratory), which are open manufacturing centres where collaboration and sharing are the core concepts.

Locations

In this spirit, and continuing the theme of the “Do It Yourself” movement, FabLabs (Fabrication Laboratory) emerged in the late 1990s, arising out of the concept dreamed up by Neil Gershenfeld, a physicist, computer scientist, and professor at MIT. The early supporters of “DIY” began to share, exchanging their know-how and creating things themselves.

These collaborative environments developed into “maker” communities that have grown throughout the U.S., Europe, and France. With 83 FabLabs recognised by MIT, France has the largest number of FabLabs in Europe (and the second-largest number in the world).

In Africa, DIY is also known as “frugal innovation” – i.e., working with what you have — which is no mean feat… For instance, in Dakar, in one of Senegal’s most innovative FabLabs (French version only), two passionate creators explore all digital avenues and share their know-how to solve both personal problems and to rise to the environmental or economic challenges facing their country.

Today, the FabLabs phenomenon reaches every sphere, turning up in the most unexpected places such as Biarne, (French version only) a village in the Jura region of France with approximately 400 inhabitants, where the first rural FabLab was established. Five years after it launched, the story so far is a very positive one, with Biarne’s “makers” proud of their FabLab which is now called “Net-IKi”. From that time, it has a hot press and 3D printer, making it a big hit with other local players: research and development groups, students, and SMEs.

Thanks to digital technology, the phenomenon is growing rapidly. As evidence, in recent years, the arrival of the 3D printer has revolutionised the design and manufacture of objects, machines, and online open source software… What’s more, in this respect, France stands out as a key player. Toulouse and Paris have recently been appointed to organise the 2018 edition of the World FabLab Conference, an event bringing together more than a thousand FabLabs from across the world, and tens of thousands of visitors. Machines that are otherwise inaccessible can even be used by the public.

The “DIY” culture has found its place in Orange Gardens

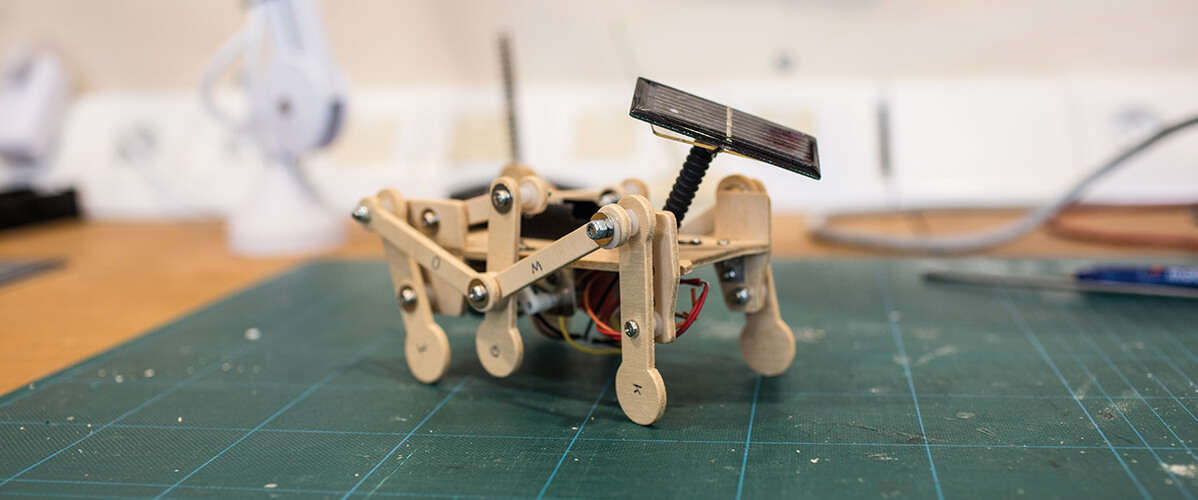

A halfway house between a workshop and a FabLab, an area has been set up on the Orange Gardens site for meeting and sharing: “The 3rd Place”. Here, the team comprised of engineers, designers, developers, and so on allows employees to learn more about the “Do It Yourself” and “Do it Together” culture. Inside, you can tinker and innovate with a wide range of tools and machines available. With a soldering iron, a 3D printer, open source software, laser cutting, a sewing machine and a digital embroiderer, there is something for every future “maker”!

The team at “The 3rd Place” has many innovative projects up its sleeve, having recently created a data object known as “The TicBot”.

The only down side, according to Lou Vettier, a “maker” and coordinator at “The 3rd Place”, is that few women visit them… One of her missions is to shake things up and make manufacturing and the tutorials offered at “The 3rd Place” more attractive to women.

Orange’s Community FabLabs, a digital remedy to combat social exclusion

A number of private foundations have also got on board to engage with community associations. Orange Solidarité (Orange Foundation) thus introduced a community aspect to FabLabs by opening its doors to young people with no qualifications to teach them about new digital practices and develop their skills, with the support of Orange employee volunteers. Edified by discussions and experience, it is a rich human adventure in community FabLabs where everyone learns something…