• To ensure that they are repaired—and, ultimately, back up and running—as fast as possible in the event of a problem, Orange has developed a solution to automate the measurement-taking process alongside Orange Marine.

Ninety-nine percent of the world’s Internet traffic passes through submarine cables, which span many thousands of kilometres. Any failure in this critical infrastructure is likely to cause major disruptions — especially in some regions where entire countries are served by a single cable.

With current methods, OTDR measurements on a 192-fibre cable would take more than 4 days, working 24 hours a day.

Technology for enhancing maintenance

This means maintenance operations on faulty cables are a race against time. At Orange Wholesale, Orange Marine teams take to the seas each day to carry out these operations, which increase in complexity and duration as cable technologies advance further. Laurent Mainguy, Measurement Expert at Orange Marine, explained: “In recent years, we have seen the advent of cables that can contain up to 192 fibres. Repairs involve carrying out optical measurements to judge the quality of splices—the welds connecting two optical fibres—using equipment. Using the methods we have today, it would take more than 4 days, working 24 hours a day, to carry out these measurements for a 192-fibre cable! Not to mention that in the near future, 244-fibre cables will begin to be rolled out. To tackle this problem, we envisaged automating this repetitive and time-consuming procedure — from configuration of the measurements to analysing the results”.

Spurred by this need, the NIF (Network Integration Factory), which develops automation software within Orange, was tasked with designing a dedicated solution capable of automating data measurement, analysis and archiving.

Ergonomic by design

Under the code name SMART (Submarine Multi-fibers Automated Reflectrometry Tests), the project began with a phase that analysed the user journey. “Putting ourselves in the shoes of the technicians on board was essential to creating the most simple, intuitive and user-friendly human-machine interface possible”, explained Nicolas Brochier, SMART Software Product Owner within the NIF. “For example, a measurement could be interrupted for various reasons. The application must therefore take this possibility into account so the user can halt and resume the process easily”.

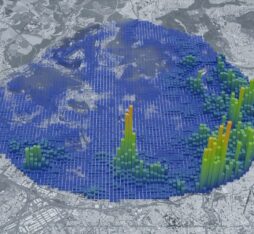

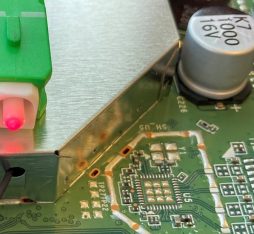

In technical terms, SMART is automation software designed for creating and instructing an end-to-end test bench, built on the connection between OTDR equipment and a cascade optical switch device. The software automatically selects the fibre to be measured and the port to which it is connected, before activating the correct OTDR device and performing a pass/fail analysis. The results are presented on a dashboard, which provides information on the condition of each weld at a glance.

From a technician’s point of view, the procedure is plain sailing: They simply connect to the ship’s internal network and run the app on any workstation to start the measurements, until an archive system stores and saves the data via an onboard server.

@Orange Marine

Significant time and efficiency gains

The innovation, which is such a simple concept as to seem almost trivial in theory, paves the way to many benefits in practice. The time saved is among the most important and tangible of these benefits — a measurement phase that previously lasted several hours now only takes around 1 hour for a 192-fibre cable, without risk of errors. Implementing SMART therefore speeds up response times and decreases the time spent at sea, all while optimising resources. What’s more, implementing the solution is a sound investment: “We rely on the equipment that is already available on board”, said Brochier. “There’s no need to invest in new equipment; the application adapts to what’s already there. It has also been designed to be future-proof and will therefore be able to accommodate new generations of OTDRs via a purpose-built library, without changing the business logic.”

The solution also adds value with its archiving and reporting capabilities. “The system saves the results from every measurement on a server, giving us a complete history of our operations that we didn’t have before”, Mainguy continued. “Using the system also makes it possible to standardise ways of working between one team—or one ship—and another. Finally, SMART improves and simplifies the work of reporting to the clients who own the cables by generating automated reports for each measurement”.

Tried and tested onshore in a cable depot, SMART will soon be put to sea aboard Orange Marine cable ships.

Optical Time-domain Reflectometer. A precise instrument used to locate and characterise incidents or defects along an optical fibre.