With the support of equipment manufacturers, data centre temperatures stabilise and energy saved on cooling can reach 90%.

Passing an electrical current through a material generates heat. This is a well-known phenomenon, named the ‘Joule effect’, after its discoverer.

At Orange, electronic equipment (IT and telecoms) consisting of silicon components and powered by electricity is not immune to this rule. “The energy consumed and heat produced by this equipment has an impact on the temperature in the buildings where the equipment is located,” says David Nörtershäuser, thermal research expert at Orange.

In addition, internet speeds continue to increase, in response to customer needs. The consequence: Orange equipment is more densely packed and the heat intensifies. “This generates a need for increasingly powerful cooling sources, which has a growing impact on energy consumption,” stresses David Nörtershäuser.

Currently, electricity bills can account for up to 50% of overall consumption at sites housing this equipment.

What’s more, European standards define temperature ranges, setting benchmarks ranging from 5 to 40 degrees for telecommunications equipment, while temperatures in data centres are still kept at between 22 and 25 degrees. Orange equipment must meet these standards.

“To date,” continues David Nörtershäuser, “the technology available has not allowed us to implement strategies to reuse all of this energy. To keep the equipment at the correct temperature, we consume energy, which we pay for, in order to remove heat that we do not recycle,” he notes. What’s more, the conventional air cooling systems typically used, which are very inefficient, are reaching the limits of their cooling capacity.

Faced with these issues and the resulting costs, Orange has decisively turned its attention to liquid cooling. This technique places a liquid cooling source in close contact with components to lower their temperature and avoid reliance on air-conditioning systems.

Three methods are currently being studied:

Mainly deployed in existing facilities, the first requires a cooling device known as an ’air-water exchanger’, located behind the telecom racks or servers, close to the electronic equipment. Its aim is to capture hot air given off by equipment, which is then converted into water and either removed from the building or used to heat the offices.

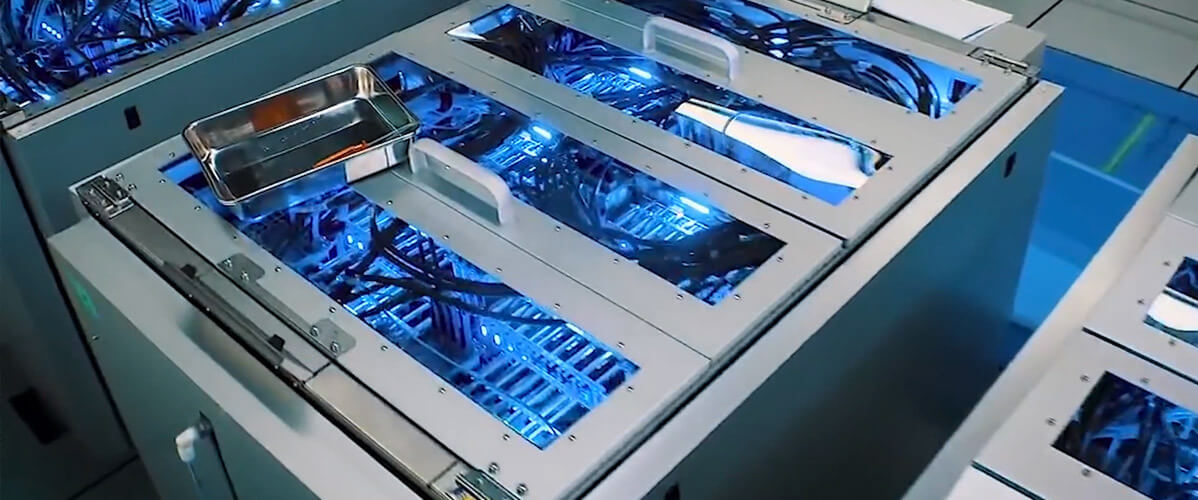

The second involves submerging electronic equipment in mineral oil baths: recently, tests have been performed in a fluorinated liquid developed by the company 3M (an Orange supplier), which will enable us to handle very high energy densities in the future. With vaporising points ranging from 45° to 49°, these fluids trap the heat given off by components. “This solution will be available in 5 to 10 years,” asserts David Nörtershäuser.

The third method was developed as part of a European project called OPERA-NET2, launched in December 2011. Several operators participated, with the assistance of equipment manufacturers such as Nokia, who are working to establish water-cooled base radio stations for the mobile network. A plate with water flowing through it is located close to the component. Through thermal conduction, heat is transferred directly to the fluid and the energy is therefore recovered via the plate.

The last of these solutions is of great interest to Orange. “The impact is very positive in terms of equipment reliability, as at the component level this system keeps temperatures more stable, and the reduction in energy used for cooling may be up to 90%.” says David Nörtershäuser.

Another advantage: it helps us increase the density of equipment per square metre and reduce surface area, as the buildings are also part of the economic equation. Orange now considers thermal management of buildings to be a solution, from the design phase. The double wall technique, in particular, is one of the equipment cooling solutions actively pursued by Orange. This is also a means of preventing the inflow of pollutants and humidity through conventional air injection methods, a common source of premature equipment failure.

The construction of internationally-patented double walls in rooms housing data centres enables us to simultaneously optimise the removal of heat produced by the machines and minimise external inflows.

“Recently, technology for removing heat generated by our equipment has moved towards containers, enabling us to rapidly roll out ’turnkey’ data centres. This is a way of bypassing the need to build complex technical rooms,” remarks David Nörtershäuser.

Implementing solutions such as liquid cooling in well-designed buildings guarantees sustainable deployment of equipment and controlled energy consumption. “Representing significant technological breakthroughs, all of these innovations, adopted by Orange, are now covered by European standardisation body specifications. This is a way of accelerating our ecosystem’s transition towards these green technologies,” concludes David Nörtershäuser.

Ultimately, these methods will be deployed in all countries where Orange operates.