● New technologies like iDEAR (Intelligent Disassembly of Electronics for Remanufacturing and Recycling), which make use of artificial intelligence and robotics, hold the promise of cleaner and more precise recycling.

● Orange is committed to a rigorous strategy for managing end-of-life equipment. The aim is to maximize the second life of equipment and build a more resource-efficient and sustainable business model.

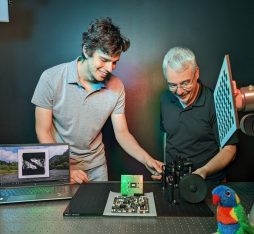

In 2022, 62 million tons of electronic waste were produced worldwide, a figure that the United Nations expects to reach 82 million tons in 2030. Only 22% of e-waste is recycled, while RFI reports that “the rest mainly ends up in the continent of Africa, where it poisons the inhabitants, the soil, the air, and the water”. In Germany, the iDEAR project at the Fraunhofer Institute for Factory Operation and Automation (IFF) is developing solutions for the automated non-destructive disassembly of electronics to facilitate recycling. The goal is to make use of robotics, AI and metrology to create a certifiable, closed-loop waste management system, which automatically identifies components and assemblies with optical sensors and 3D cameras. By facilitating more efficient disassembly, the system will optimize the use of natural resources, thereby reducing the need for mining and production of new raw materials.

The initiative has a lot in common with the European Union ReconCycle project which also aims to take advantage of “advances in robotics and AI to tackle the complexities of e-waste recycling, promoting sustainability and innovation in the circular economy”. Focusing on self-reconfigurable hardware and software for the disassembly of electronic devices, Reconcycle has developed a robotic cell, which uses sensorimotor learning techniques – an AI approach which enables a robot to learn by acting and observing the effects of its actions – as well as artificial intelligence models.

It is also increasingly important for us to collaborate on decarbonization strategies with the makers of new phones

The long-term vision embraced by Orange

In 2023, Orange generated a combined total of 4,205 tonnes of electronic waste across a number of different categories. “All of the waste electrical and electronic equipment (WEEE) is dispatched to certified recycling operations, mainly via producer responsibility organizations in Europe,” explains Orange Circular Economy Manager Julie Allagnat. The group does not directly take charge of recycling (which is entrusted to subcontractors), however, Orange is careful to ensure that processes are fully traceable and conducted in full compliance with environmental standards. “Our aim is to ensure that end-of-life equipment is transferred to specialized organizations in order to manage risks and ensure compliance with current regulations, while optimizing our waste collection and treatment performance.” Orange is currently focused on the collection and processing of waste generated by its telecommunications business, in particular decommissioned network infrastructure. It also has priority programmes for hazardous waste in WEEE and WEEE batteries.

Recycling and the circular economy

Going beyond simple waste collection, Orange also actively develops reverse supply chain initiatives to maximize the second life of equipment. “In collaboration with specialist partners such as Ingram Micro Services, we are able to refurbish up to 70% of Liveboxes returned by customers: a process that involves secure data erasure and hardware and software updating, which has enabled us to return up to 4.5 million boxes to the French market every year,” points out Pary Arpoudam, Head of Reverse Logistics Domain at Orange. The strategy is contributing to Orange Group’s drive to reduce CO2 emissions by 45% by 2030 and to achieve net-zero emissions by 2040.

In the area of handsets, the market for refurbished smartphones, which is growing twice as fast as the market for new devices, is increasing at an annual rate of 8% to 10% in Europe. “In France, refurbished devices now account for 15% to 20% of all smartphone sales, which is why it is increasingly important for us to collaborate on decarbonization strategies with the makers of new phones, and to ensure that they support our drive to reduce carbon emissions,” explains Jean-Luc Vallejo, SVP for Devices Circularity and Sustainability at Orange. According to current estimates, the carbon footprint of a refurbished smartphone is 80% lower than for a new device. “However, the market for refurbished smartphones, which is fragmented and involves processes that are hard to automate, still faces difficulties. As it stands, it is not easy to guarantee sufficient volumes,” adds Vallejo. Work is also underway to promote a circular economy for IT and network equipment (ITN), which could benefit from more mature refurbishment programmes. Reducing the significant carbon footprint generated by the use phase of this equipment will be a key priority for Orange over the next few years.

Sources :

Intelligent Disassembly of Electronics for Remanufacturing and Recycling (iDEAR Project) (en anglais)

Read more :

AI will add to the e-waste problem. Here’s what we can do about it. (en anglais)

AI-powered robots help tackle Europe’s growing e-waste problem (en anglais)

Julie Allagnat

Julie Allagnat

Pary Arpoudam

Pary Arpoudam

Jean-Luc Vallejo

Jean-Luc Vallejo